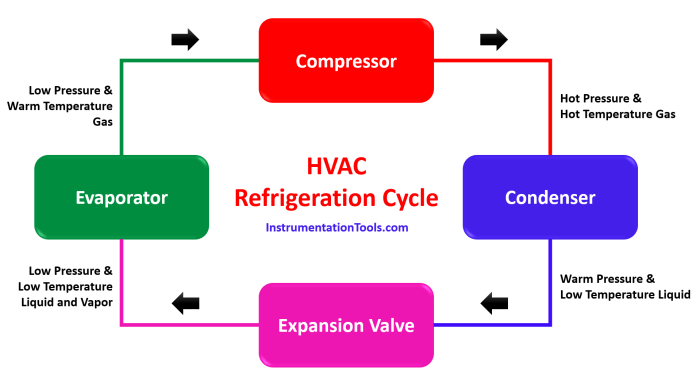

The three processes commonly used to describe refrigerant handling are recovery, reclamation, and recycling. These processes are essential for the safe and environmentally friendly handling of refrigerants, which are used in a wide variety of applications, including refrigeration, air conditioning, and heat pumps.

Refrigerant recovery involves removing refrigerant from a system, while refrigerant reclamation involves cleaning and purifying the refrigerant so that it can be reused. Refrigerant recycling involves reusing refrigerant that has been recovered from a system without first reclaiming it.

Refrigerant Handling

Refrigerant handling involves various processes essential for the safe and efficient operation of refrigeration and air conditioning systems. These processes include recovery, reclamation, recycling, disposal, leak detection, and repair. Each process plays a specific role in managing refrigerants, ensuring their proper handling and minimizing their environmental impact.

Recovery, The three processes commonly used to describe refrigerant handling are

Refrigerant recovery is the process of removing refrigerant from a refrigeration or air conditioning system. This is typically done when a system is being serviced, repaired, or decommissioned. The recovery process involves using a recovery machine to extract the refrigerant from the system and store it in a recovery cylinder.Methods

used for refrigerant recovery include:

- Vapor recovery: The refrigerant is recovered in its gaseous state using a recovery machine.

- Liquid recovery: The refrigerant is recovered in its liquid state using a recovery machine.

- Pump-out recovery: The refrigerant is recovered using a vacuum pump.

Equipment utilized for refrigerant recovery includes:

- Recovery machines: These machines are designed to extract refrigerant from a system and store it in a recovery cylinder.

- Recovery cylinders: These cylinders are used to store recovered refrigerant.

- Vacuum pumps: These pumps are used to create a vacuum in a system to remove refrigerant.

Reclamation

Refrigerant reclamation is the process of purifying and recycling recovered refrigerant. This process involves removing contaminants, such as moisture, oil, and other impurities, from the refrigerant. The reclaimed refrigerant can then be reused in refrigeration and air conditioning systems.Steps involved in refrigerant reclamation include:

- Filtering: The recovered refrigerant is passed through a filter to remove solid contaminants.

- Dehydration: The refrigerant is passed through a dehydrator to remove moisture.

- Distillation: The refrigerant is distilled to remove impurities and separate it from oil.

- Analysis: The reclaimed refrigerant is analyzed to ensure that it meets the required purity standards.

Benefits of refrigerant reclamation include:

- Reduced environmental impact: Reclamation helps to reduce the release of refrigerants into the atmosphere, which can contribute to global warming and ozone depletion.

- Cost savings: Reclaimed refrigerant is typically less expensive than new refrigerant.

- Conservation of resources: Reclamation helps to conserve natural resources by recycling used refrigerant.

Recycling

Refrigerant recycling is the process of reusing recovered refrigerant without further purification. This process involves removing contaminants, such as moisture and oil, from the recovered refrigerant, but it does not involve distillation. The recycled refrigerant can then be reused in refrigeration and air conditioning systems.Advantages

of refrigerant recycling include:

- Reduced environmental impact: Recycling helps to reduce the release of refrigerants into the atmosphere, which can contribute to global warming and ozone depletion.

- Cost savings: Recycled refrigerant is typically less expensive than new refrigerant.

Disadvantages of refrigerant recycling include:

- Limited use: Recycled refrigerant may not be suitable for use in all refrigeration and air conditioning systems.

- Potential for contamination: Recycled refrigerant may contain impurities that can contaminate the system.

Equipment used for refrigerant recycling includes:

- Recycling machines: These machines are designed to remove contaminants from recovered refrigerant and store it in a recycling cylinder.

- Recycling cylinders: These cylinders are used to store recycled refrigerant.

Expert Answers: The Three Processes Commonly Used To Describe Refrigerant Handling Are

What are the three processes commonly used to describe refrigerant handling?

The three processes commonly used to describe refrigerant handling are recovery, reclamation, and recycling.

What is the difference between refrigerant recovery and refrigerant reclamation?

Refrigerant recovery involves removing refrigerant from a system, while refrigerant reclamation involves cleaning and purifying the refrigerant so that it can be reused.

What are the advantages of refrigerant recycling?

Refrigerant recycling can save money and reduce the environmental impact of refrigerant use.