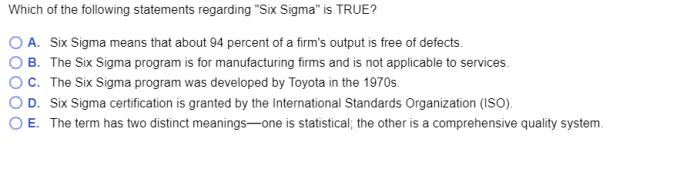

Which of the following statements regarding Six Sigma is true? Six Sigma is a quality control methodology that aims to improve processes by identifying and eliminating defects. It is a data-driven approach that uses statistical analysis to identify the root causes of problems and develop solutions to prevent them from recurring.

Six Sigma has been successfully implemented in a wide range of industries, including manufacturing, healthcare, and finance.

The key principles of Six Sigma are:

- Customer focus:Six Sigma is focused on meeting the needs of customers by identifying and eliminating defects that can impact customer satisfaction.

- Data-driven decision-making:Six Sigma uses statistical analysis to identify the root causes of problems and develop solutions that are based on data.

- Continuous improvement:Six Sigma is a continuous improvement process that is always looking for ways to improve processes and eliminate defects.

Definition and Overview

Six Sigma is a data-driven quality improvement methodology that aims to reduce defects and improve processes within an organization. It is based on the statistical concept of sigma, which represents the standard deviation of a process from its target value.

Six Sigma was developed by Motorola in the 1980s as a way to improve the quality of its manufacturing processes. It has since been adopted by organizations in various industries, including healthcare, finance, and service.

Goals and Objectives: Which Of The Following Statements Regarding Six Sigma Is True

The primary goal of Six Sigma is to improve quality and reduce defects. This is achieved by identifying and eliminating the root causes of defects and improving processes to prevent their recurrence.

Six Sigma projects typically aim to achieve the following objectives:

- Reduce defects to a level of 3.4 per million opportunities (ppm)

- Improve customer satisfaction

- Increase productivity

- Reduce costs

Methodology and Tools

Six Sigma projects follow a structured methodology known as DMAIC (Define, Measure, Analyze, Improve, Control):

- Define:Identify the problem or opportunity for improvement.

- Measure:Collect data to understand the current state of the process.

- Analyze:Use statistical tools to identify the root causes of the problem.

- Improve:Implement solutions to eliminate the root causes.

- Control:Monitor the process to ensure that the improvements are sustained.

Six Sigma projects also employ a variety of tools and techniques, including:

- Statistical analysis

- Process mapping

- Root cause analysis

- Design of experiments

Benefits and Impact

Organizations that successfully implement Six Sigma can experience a range of benefits, including:

- Improved customer satisfaction

- Increased productivity

- Reduced costs

- Enhanced competitiveness

Examples of organizations that have successfully implemented Six Sigma include:

- General Electric

- Toyota

- Honeywell

- Bank of America

Challenges and Limitations

While Six Sigma can be a powerful tool for improving quality, there are also some challenges and limitations associated with its implementation:

- Lack of buy-in:It is important to secure buy-in from all levels of the organization, from top management to front-line employees.

- Resistance to change:Six Sigma projects often require changes to processes and systems, which can lead to resistance from employees.

- Insufficient resources:Six Sigma projects can be time-consuming and resource-intensive, and it is important to have the necessary resources in place before embarking on a project.

Variations and Adaptations

There are a number of variations and adaptations of Six Sigma, including:

- Lean Six Sigma:Combines the principles of Six Sigma with Lean manufacturing techniques to focus on reducing waste and improving flow.

- Design for Six Sigma (DFSS):Focuses on designing new products and processes that are inherently Six Sigma compliant.

These variations and adaptations address specific business needs and industries, and can be customized to meet the unique requirements of an organization.

Current Trends and Future Directions

Six Sigma is a constantly evolving field, and there are a number of current trends and emerging practices that are shaping its future:

- Increased use of data analytics:Big data and advanced analytics are being used to improve the accuracy and effectiveness of Six Sigma projects.

- Focus on customer experience:Six Sigma is increasingly being used to improve customer experience and satisfaction.

- Integration with other quality improvement methodologies:Six Sigma is being integrated with other quality improvement methodologies, such as Lean and Agile, to create a more comprehensive approach to quality management.

The future of Six Sigma is bright, and it is likely to continue to play a major role in improving quality and efficiency in organizations.

Detailed FAQs

What are the benefits of Six Sigma?

Six Sigma can help organizations improve processes, reduce defects, and increase customer satisfaction. It can also lead to increased productivity, reduced costs, and improved employee morale.

What are the challenges of Six Sigma implementation?

The challenges of Six Sigma implementation can include lack of buy-in from leadership, resistance to change from employees, and insufficient resources.

How can I learn more about Six Sigma?

There are many resources available to learn more about Six Sigma, including books, articles, and online courses. You can also find Six Sigma training programs offered by many organizations.