National electrical code article 590 – National Electrical Code (NEC) Article 590 plays a crucial role in safeguarding electrical safety in commercial and industrial settings. This comprehensive article establishes essential requirements for electrical installations, specific equipment and systems, hazardous locations, and inspection and maintenance procedures. Understanding and adhering to NEC Article 590 is paramount for ensuring the safety of occupants and preventing electrical hazards.

This article will delve into the key provisions of NEC Article 590, providing a thorough overview of the requirements for electrical installations in commercial and industrial occupancies. We will explore the specific regulations for wiring methods, overcurrent protection, grounding and bonding, motors and motor controllers, transformers, generators, hazardous locations, and inspection and maintenance.

By examining case studies and examples, we will gain practical insights into the application of NEC Article 590 in real-world scenarios.

Introduction

The National Electrical Code (NEC) Article 590 establishes comprehensive requirements for the electrical safety of commercial and industrial occupancies, aiming to minimize the risk of electrical hazards and ensure the well-being of occupants.

NEC Article 590 plays a pivotal role in safeguarding lives and property by providing detailed guidelines for the design, installation, and maintenance of electrical systems in these occupancies. Its adherence ensures that electrical installations meet rigorous safety standards, mitigating potential electrical hazards that could result in fires, electric shocks, or other dangerous situations.

Scope, National electrical code article 590

- NEC Article 590 applies to all commercial and industrial occupancies, including but not limited to:

- Office buildings

- Retail stores

- Warehouses

- Factories

- Hospitals

- Schools

Requirements for Electrical Installations: National Electrical Code Article 590

Electrical installations in commercial and industrial occupancies must meet specific requirements to ensure safety and functionality. These requirements cover various aspects of electrical systems, including wiring methods, overcurrent protection, and grounding and bonding.

Wiring Methods

The National Electrical Code (NEC) Artikels specific wiring methods that must be used in commercial and industrial occupancies. These methods include:

- Conduit: Conduit is a protective pipe that houses electrical wires and cables. It provides mechanical protection and prevents damage from environmental factors.

- Cable trays: Cable trays are metal structures that support and route electrical cables. They provide a flexible and cost-effective method of installing cables.

- Busways: Busways are enclosed electrical distribution systems that distribute power to multiple loads. They offer a compact and efficient method of power distribution.

Specific Equipment and Systems

In commercial and industrial occupancies, the NEC sets forth specific requirements for electrical equipment and systems to ensure their safe and reliable operation.

These requirements address the installation, operation, and maintenance of various types of equipment, including motors, transformers, and generators, to minimize electrical hazards and protect personnel and property.

Motors and Motor Controllers

- Motors and motor controllers must be installed in accordance with the manufacturer’s instructions and applicable NEC requirements.

- Motors must be properly sized and protected against overloads, short circuits, and other potential hazards.

- Motor controllers must be capable of starting and stopping the motor safely and efficiently.

Transformers

- Transformers must be installed in accordance with the manufacturer’s instructions and applicable NEC requirements.

- Transformers must be properly sized and protected against overloads, short circuits, and other potential hazards.

- Transformers must be installed in a location that provides adequate ventilation and protection from the elements.

Generators

- Generators must be installed in accordance with the manufacturer’s instructions and applicable NEC requirements.

- Generators must be properly sized and protected against overloads, short circuits, and other potential hazards.

- Generators must be installed in a location that provides adequate ventilation and protection from the elements.

Hazardous Locations

Hazardous locations are areas where flammable gases, vapors, or liquids are present in sufficient quantities to create a risk of fire or explosion. The National Electrical Code (NEC) classifies hazardous locations into three classes, depending on the type of hazard present:

Class I:Locations where flammable gases or vapors are present in sufficient quantities to be ignited by a spark or other source of ignition.

Class II:Locations where combustible dust is present in sufficient quantities to be ignited by a spark or other source of ignition.

Class III:Locations where easily ignitable fibers or flyings are present in sufficient quantities to be ignited by a spark or other source of ignition.

The NEC requires that electrical installations in hazardous locations be designed and installed to minimize the risk of fire or explosion. This includes using equipment that is specifically designed for use in hazardous locations and following specific wiring methods.

Types of Equipment

The NEC requires that electrical equipment used in hazardous locations be listed for use in the specific type of hazard present. Listed equipment has been tested and approved by a qualified testing laboratory to ensure that it meets the requirements of the NEC.

Some of the types of equipment that are commonly used in hazardous locations include:

- Explosion-proof equipment

- Dust-ignition-proof equipment

- Intrinsically safe equipment

- Non-incendive equipment

Wiring Methods

The NEC requires that wiring methods used in hazardous locations be designed to minimize the risk of fire or explosion. This includes using wiring methods that are specifically designed for use in hazardous locations and following specific installation practices.

Some of the wiring methods that are commonly used in hazardous locations include:

- Conduit

- Cable tray

- Open wiring

- Busways

The NEC also requires that electrical installations in hazardous locations be inspected and maintained on a regular basis to ensure that they are in good working order and that they continue to meet the requirements of the NEC.

Inspection and Maintenance

Regular inspection and maintenance of electrical installations are crucial for ensuring the safety and reliability of commercial and industrial occupancies. The National Electrical Code (NEC) provides specific requirements for inspection and maintenance to minimize electrical hazards and ensure compliance with safety standards.

The importance of regular inspections and testing cannot be overstated. They help identify potential electrical hazards, such as loose connections, damaged insulation, or overloaded circuits, before they can cause serious accidents or equipment failures. By proactively addressing these issues, businesses can prevent costly downtime, protect employees and customers from electrical shock or fire, and maintain the integrity of their electrical systems.

Inspection Frequency

The NEC requires regular inspections of electrical installations to ensure they are maintained in accordance with the code. The frequency of inspections depends on the type of occupancy and the level of electrical hazard present.

- Commercial occupancies:At least every three years, or more frequently if conditions warrant.

- Industrial occupancies:At least annually, or more frequently if conditions warrant.

Inspection Scope

Inspections should be thorough and cover all aspects of the electrical installation, including:

- Service entrance equipment

- Distribution panels and switchboards

- Branch circuits and feeders

- Lighting fixtures and outlets

- Grounding and bonding

- Overcurrent protection devices

Maintenance Procedures

In addition to regular inspections, electrical installations require ongoing maintenance to ensure their proper operation and safety. Maintenance procedures may include:

- Cleaning and tightening electrical connections

- Replacing worn or damaged components

- Testing and calibration of protective devices

- Updating electrical systems to meet current codes and standards

Case Studies and Examples

NEC Article 590 provides a comprehensive set of requirements for the installation and maintenance of electrical equipment in hazardous locations. These requirements are essential for ensuring the safety of personnel and property in these potentially dangerous environments.

There are numerous examples of how NEC Article 590 has been applied in real-world scenarios. One example is the use of explosion-proof electrical equipment in a chemical plant. The plant produces chemicals that are highly flammable, so it is essential that all electrical equipment in the plant be designed to prevent the ignition of these chemicals.

Another example of the application of NEC Article 590 is the use of intrinsically safe electrical equipment in a coal mine. Coal mines are filled with methane gas, which is highly explosive. Intrinsically safe electrical equipment is designed to prevent the ignition of methane gas, even in the event of a fault.

Challenges and Solutions

There are a number of challenges that can be encountered in implementing NEC Article 590 requirements. One challenge is the cost of explosion-proof and intrinsically safe electrical equipment. This equipment can be significantly more expensive than standard electrical equipment.

Another challenge is the need to modify existing electrical installations to comply with NEC Article 590 requirements. This can be a time-consuming and expensive process.

However, there are a number of solutions that can be used to overcome these challenges. One solution is to use less expensive non-incendive electrical equipment in place of explosion-proof equipment. Non-incendive equipment is not designed to prevent the ignition of flammable gases, but it is designed to prevent the propagation of flames.

Another solution is to use intrinsically safe electrical equipment in place of explosion-proof equipment. Intrinsically safe equipment is designed to prevent the ignition of flammable gases, even in the event of a fault.

FAQ Insights

What is the purpose of NEC Article 590?

NEC Article 590 establishes requirements for electrical installations in commercial and industrial occupancies to ensure electrical safety and minimize hazards.

What are the key requirements of NEC Article 590?

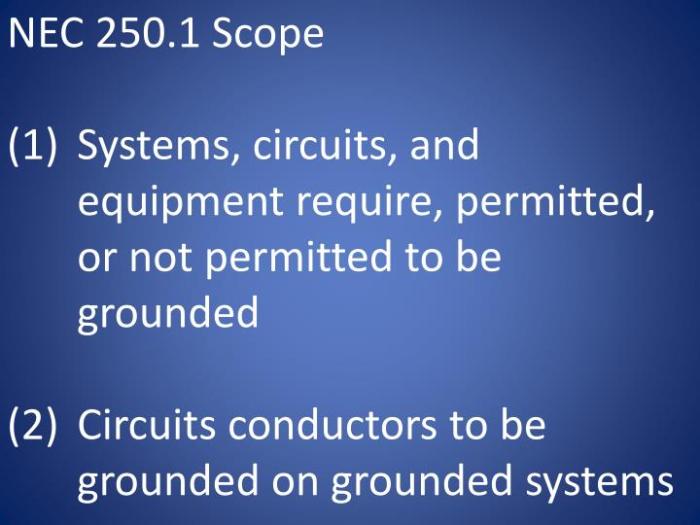

NEC Article 590 covers a wide range of requirements, including wiring methods, overcurrent protection, grounding and bonding, specific equipment and systems, hazardous locations, and inspection and maintenance.

Who should be familiar with NEC Article 590?

Electrical contractors, inspectors, engineers, and anyone involved in the design, installation, or maintenance of electrical systems in commercial and industrial occupancies should be familiar with NEC Article 590.